Tapovan Foods (Brand: Testo)

End‑to‑end product development support and process optimization for branded food products.

A team driven by experts with Proven track record in driving consumer‑centric product innovation across juices, spices, culinary products, frozen foods, and natural beverages like fruit juices, coconut water, milk, and tea..

Read MoreGuide food and beverage innovators from first trials to full‑scale plants, creating the next generation of high‑quality, compliant, and profitable products.

Practical on‑ground experience with process innovation, smart packaging solutions, & clear guidance at every stage of the journey—from concept & trials to compliant, full‑scale production

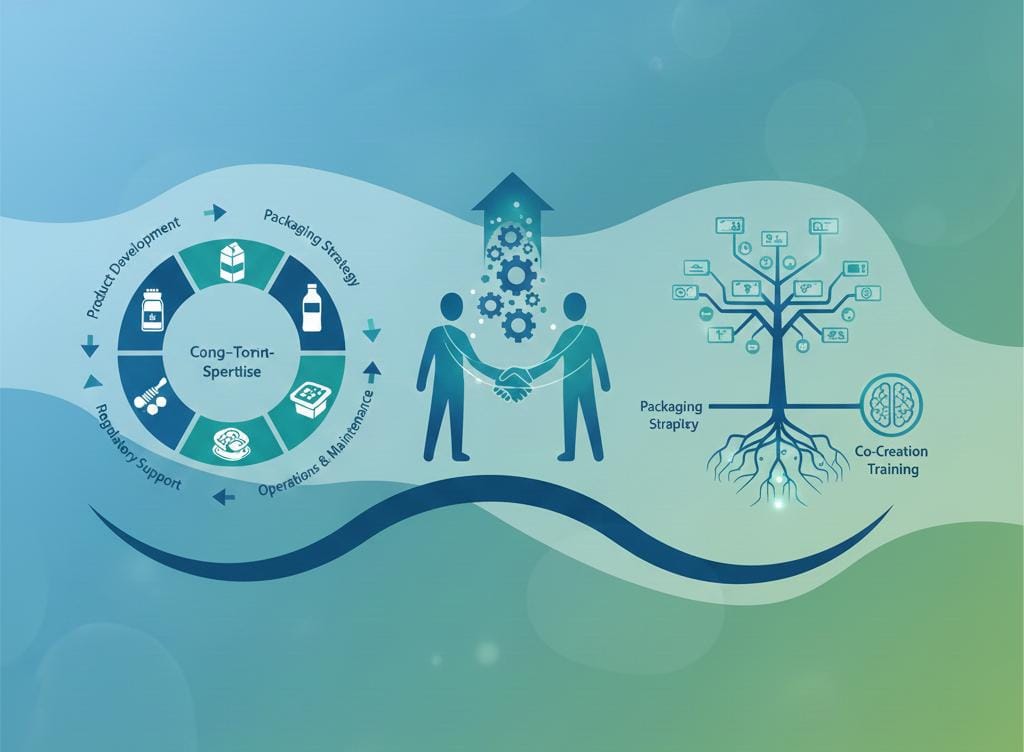

Craft and refine recipes for food, beverage, spices, honey, dairy, and ready‑to‑eat products to achieve the right balance of taste, texture, nutrition, and shelf life.

We work with you from lab trials to pilot batches, ensuring each formulation is commercially viable and aligned with regulatory requirements.

Design efficient, scalable processing lines and plant layouts tailored to your product category, capacity, and budget.

The focus is on hygiene, safety, throughput, and compliance, so you can move confidently from small‑scale trials to full‑scale production.

Recommend and develop packaging formats that protect product quality, extend shelf life, and communicate your brand promise effectively.

From material selection to pack format and labeling guidance, the goal is to balance safety, cost, sustainability, and shelf impact.

Ensure smooth, reliable running of your processing and packaging lines through structured operations and maintenance support.

This includes SOP design, staff training, preventive maintenance planning, and on‑call troubleshooting to minimize downtime and protect product quality.

Krishnadaya brings together a multidisciplinary team of visionary leaders, consultants, and engineers dedicated to food, beverage, spices, honey, dairy, and ready‑to‑eat innovation.

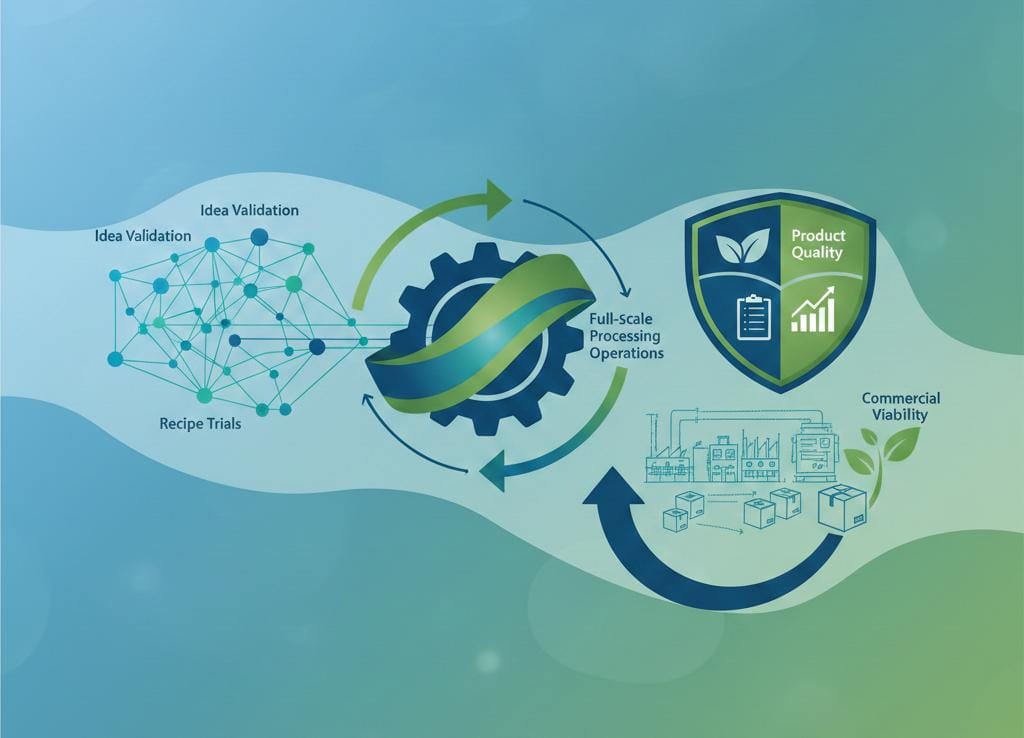

We support you from idea validation and recipe trials to full‑scale processing, packaging, and operations, so you do not need multiple fragmented partners.

Our approach balances product quality, regulatory compliance, and commercial viability to help build safe, scalable, and profitable products.

We combine plant‑floor experience with process and packaging design to deliver solutions that work in real operating conditions.

Our services span product development, process and plant design, packaging strategy, regulatory and quality support, and operations & maintenance.

With focused experience across spices, honey, dairy, beverages, and RTE formats, our guidance is tailored to the nuances of each segment.

Krishnadaya works as a long‑term partner—co‑creating roadmaps, training teams, and continuously improving processes to sustain growth and innovation.

End‑to‑end support for juices, beverages, snacks, condiments, and packaged foods, from idea validation and recipe trials to scalable processing, packaging, and commercialization.

Specialized guidance for spice processors and blenders to achieve consistent flavor, hygiene, and export‑ready quality through optimized processing lines and packaging choices.

Support for honey and natural product brands focusing on purity, traceability, and premium positioning with appropriate processing, filtration, and packaging systems.

Process and packaging solutions for milk, fermented products, and nutritional lines, helping units modernize operations, extend shelf life, and maintain stringent quality standards.

Consulting for ready‑to‑eat and ready‑to‑cook foods, covering formulation, thermal processing or freezing, and packaging that ensure safety, convenience, and stable shelf life.

Support for brands working on fortified, functional, or wellness‑oriented products to align formulations, processes, and packaging with evolving health and regulatory expectations.

Services for manufacturers targeting international markets, focusing on compliance, documentation, labeling, and packaging standards required by different countries.

Assistance for contract manufacturers and private‑label units to optimize capacity utilization, standardize quality, and handle multi‑brand, multi‑SKU operations efficiently.

Turning complex food ideas into market‑ready products with a full‑stack innovation team.

Food manufacturing and packing starts with idea generation and moves into R&D and innovation labs where formulas are created, taste panels are run and consumer research is conducted.

Products undergo pilot testing in selected markets, followed by machinery identification, purchasing and installation, trial production, filling and sealing, labelling and packing.

With our dedicated Krishnadaya team, entrepreneurs receive hands‑on support to ensure each launch is smooth, compliant and ready for scale.

Team Visual Placeholder

Replace this block with a photo of your team, your R&D lab or a collage of factory and innovation activities.

More than 40 years of combined experience in product development, food manufacturing and packing, with strong vendor and third‑party networks.

Support for FSSAI licences, testing laboratory identification and consumer research in Hyderabad, Bengaluru, Chennai, Coimbatore, Delhi / NCR and Pune.

We do more than supply individual machines or ingredients. Your project receives integrated support across machinery selection, food ingredients, process know‑how and on‑ground implementation.

This approach helps entrepreneurs reduce trial‑and‑error, speed up launch timelines and maintain consistent quality in production.

Whether you are building a new facility or expanding an existing one, our team aligns machinery, ingredients and knowledge transfer into one continuous solution.

Visual Placeholder

Replace with a photo or graphic showing machinery, ingredients and packaged products together.

Krishnadaya brings together a multidisciplinary team of leaders, consultants and engineers delivering solutions across food, beverage, spices, honey, dairy and ready‑to‑eat categories.

End‑to‑end product development support and process optimization for branded food products.

Processing of honey, aloe vera, amla and jamun into energy bars, protein bars and fruit bars.

Juice processing setup and optimization from raw fruit to bottled product.

Health juice formulation, scale‑up and quality‑focused process design.

Process design and quality systems for a diversified food product portfolio.

Standardized spice processing with a focus on consistency and safety.

Technical support for food processing plants, including layout, commissioning and staff training.

Pomegranate processing, yield improvement and packaging solutions.

Litchi processing line design and optimization.

Satellite units for litchi, pineapple, mango and pink guava, from design to operator training.

If you’re planning your own food manufacturing project – or want to partner with us to serve your local market – get in touch with our team today.

Make an Appointment